Summary

Objectives

Compression wood is a type of reaction wood that forms in conifers on the underside of leaning stems, on the leeward side of trees exposed to strong winds, in crooked stems and in the lower part of trees growing on a slope. The structure and chemical composition of compression wood differ from those of normal wood. These differences result in a deterioration in mechanical properties (strength and stiffness) and increased drying distortion. Compression wood can be a cause of major problems in the wood processing industry.

The overall aim of this project is to obtain a long-term improvement in the quality of European softwood timber products, in terms of mechanical properties and geometrical stability related to the occurrence of compression wood. The species being studied are Norway spruce, Sitka spruce, Scots pine and European larch. The project has ten participating organisations representing research institutes and industry partners in Finland, France, Germany, Great Britain, Italy and Sweden.

The key elements of the project are:

- To improve and standardise methods for identifying and quantifying the presence of compression wood, from the laboratory through to the industrial level

- To increase understanding of the way in which compression wood is formed in relation to stem form, site factors and silvicultural practices

- To develop models and decision support tools predicting the occurrence and distribution of compression wood within individual tree stems and between trees growing under different site and silvicultural conditions

- To develop silvicultural strategies to minimise the development of compression wood in growing trees

- To develop industrial processing techniques to minimise the impact of compression wood on end-product performance

Results and milestones

During the first twelve months of the project the majority of work has been concentrated in two main areas:

- Fieldwork to obtain stand measurements and timber samples

- The development of protocols, methodologies and equipment for the characterisation of compression wood in samples at both the industrial and the laboratory level.

A total of 30 sample stands have been identified representing variations in slope, wind exposure, spacing, age and silvicultural system. Site, stand and sample tree characterisation has been completed according to an agreed protocol in two-thirds of the sample stands, as shown in the table below. 240 sample trees have been felled and sample discs cut for laboratory studies, while a further 138 trees have been felled and logs extracted for industrial evaluation.

| Species | Country | No. of sites or stands | No. assessed to date | Variables being studied |

|---|---|---|---|---|

| Sitka spruce | Britain |

8 |

6 |

Wind exposure, slope & spacing |

| Norway spruce | Sweden |

2 |

– |

Age/species mixture |

| Norway spruce | Germany |

4 |

2 |

Wind exposure and silviculture |

| Norway spruce | France |

4 |

4 |

Slope |

| European larch | Italy |

2 |

2 |

Natural and plantation stands |

| European larch | Germany |

2 |

– |

Age and silviculture |

| Scots pine | Finland |

4 |

4 |

Spacing |

| Scots pine | Sweden |

2 |

2 |

Age |

| Scots pine | Britain |

2 |

– |

Spacing |

| Total |

30 |

20 |

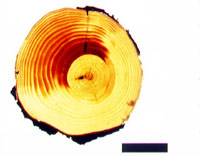

A review of literature relating to the detection and classification of compressions wood has been undertaken. A preliminary system for classifying compression wood severity in cross-sectional discs, based on a visual assessment of wood colour, has been agreed for use within the project. Trials of various image analysis software packages, which facilitate semi-automated analysis of the compression wood content of sample material, have been successfully completed.

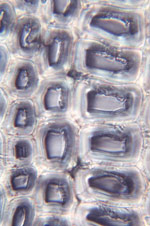

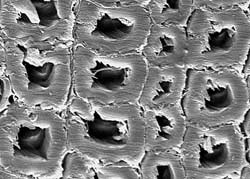

Techniques and equipment to characterise compression wood at the laboratory level in terms of anatomy, ultrastructure, biochemistry and mechanical properties have been developed and tested. The methodologies successfully used in pilot studies include x-ray densitometry, infrared spectroscopy, scanning electron microscopy and x-ray diffractometry.

At the industrial scale sample logs have been sawn into battens and kiln dried in collaboration with industrial partners. Assessments of drying distortion have been made and preliminary mechanical testing of sawn timber has begun.

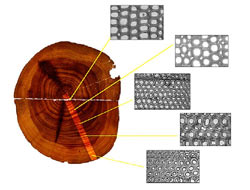

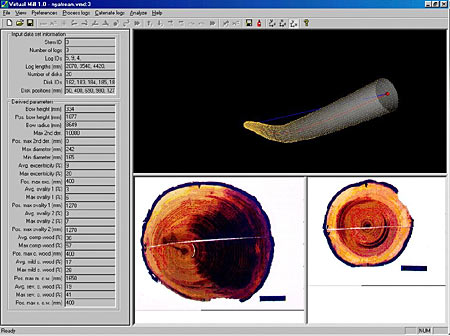

Initial work modelling the distribution of compression wood has included a pilot study to test a model predicting the location of compression wood within a tree on the basis of external stem shape. External log geometry variables from 3D images of scanned logs have also been used to develop a model of compression wood distribution within sawlogs.

Benefits and beneficiaries

Close collaboration with industry and wide dissemination of project results are key elements of the Compression Wood project. Work has been carried out both collectively by all participants and separately in each of the participating countries to liaise with the forest industry and publicise the ongoing activities within the project. These web pages providing an overview of the project and contact details for all participants, were established at an early stage.

In order to gauge the awareness within industry of compression wood as a timber defect, and to assess the perception of its effects on utilisation, a questionnaire has been devised and will be widely distributed in the participating countries. The results of this questionnaire will be summarised in a common report to provide an overview of the impact of compression wood on end-use at a European level. A number of other initiatives have been taken to publicise the project and obtain feedback through seminars, newsletters, end-user groups and articles in relevant publications.

Existing knowledge and expertise have been rationalised and combined within this project to bring a common approach to the subject of compression wood across a range of species growing in different site conditions in countries throughout Europe. The results and conclusions that will be generated during the remainder of the project will, therefore, be widely applicable both within the scientific community and in industry.

Innovative techniques using new methods and equipment have been developed for the characterisation of compression wood, and these will be available for subsequent application in other areas of wood science. The linking of detailed evaluation at the laboratory level to industrial processing and the impact of compression wood on the mechanical properties and drying behaviour of sawn timber, will facilitate optimised utilisation of the European softwood resource and improve financial return.

Future actions

During the next 12 months the remainder of the sample stands will be assessed and logs and discs cut for evaluation. The majority of laboratory and industrial experimental work will be completed, and the information obtained will be used in the development of prototype compression wood distribution models. Close liaison with industry and wide dissemination of results will continue to be a key element of the project.

Compression Wood – Anatomical properties

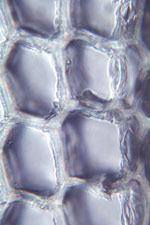

Light microscopy of compression wood in Sitka spruce

Photographs Forest Research

Severe compression wood

Normal latewood

Normal earlywood

Scanning Electron microscopy of compression wood in Sitka spruce

Photograph courtesy of Centre for Ecology and Hydrology

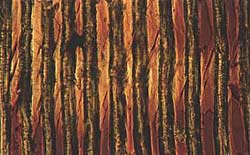

Measurement of microfibril angle

Photographs courtesy of University of Florence

Each single portion of the ring(EW and LW) are subjected to stress cycles (wetting and drying).

Each single portion of the ring(EW and LW) are subjected to stress cycles (wetting and drying).

Microscopic section of 15-18 m in thick are cut and coloured using iodine solution, according to Senft & Bensted method.

25 angles measured for each portion of annual ring.

Microscopic examination of compression wood in larch

Photograph courtesy of University of Florence

Compression Wood – Example of sample stands used for research

Sitka spruce spacing experiment – Scotland

Sitka spruce spacing experiment – Finland

Sitka spruce – West Scotland

On level site

On steep site

Scots pine – Sweden

Measuring stem shape

Compression wood

Larch – Italy

Natural larch stand

Plantation larch stand

Compression Wood – Example of sample stands used for research

Sitka spruce spacing experiment – Scotland

Sitka spruce spacing experiment – Finland

Sitka spruce – West Scotland

On level site

On steep site

Scots pine – Sweden

Measuring stem shape

Compression wood

Larch – Italy

Natural larch stand

Plantation larch stand

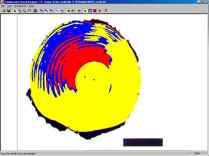

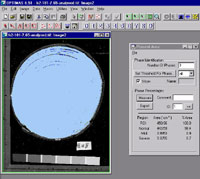

Compression Wood – Image analysis

Compression wood detection in Scots pine viewed in transmitted light

Using Compression Wood Analysis 1.0 software (Dianthus/SLU)

Photograph courtesy of Swedish University of Agricultural Sciences

Compression wood detection in Norway spruce

Photographs courtesy of University of Freiburg

Compression wood detection in Sitka spruce viewed in reflected light

Using Optimas 6.5 (Media Cybernetics) image analysis software

Photographs Forest Research

Use of a digitiser to assess the disc and ring shapes, and shape of the zone of compression wood

Photographs courtesy of Institut National de la Recherché Agronomique (INRA) – France

Image of the disc

Results of the automated treatment

DistPG : disc eccentricity

CWAS : compression wood angular sector (between the two green lines).

CWMP : compression wood angular sector mean position

In blue, the geometric centre of the disc (big square) and the geometric centre of the compression wood area (little square)

Compression Wood – Industrial scale testing

Sawing of Sitka spruce at Adam Wilson’s sawmill, Troon

Photograph Forest Research and Building Research Establishment

Assessment of drying distortion

Photographs courtesy of Swedish University of Agricultural Sciences

Compression Wood – Modelling

Modelling Compression Wood in logs

Photograph courtesy of Swedish University of Agricultural Sciences

Compression Wood – Sample logs

Extraction of larch sample logs – Italy

Sitka spruce – Scotland

Sitka spruce marked for cutting into sample discs

Sitka spruce marked logs at roadside”