Woodfuels are of relatively low energy density, compared with fossil alternatives, and consequently large volumes are typically required to be stored and transported, both into the storage receptacle and from it to the energy conversion equipment.

Woodfuels are of relatively low energy density, compared with fossil alternatives, and consequently large volumes are typically required to be stored and transported, both into the storage receptacle and from it to the energy conversion equipment.

Biomass does not generally flow as freely as oil or natural gas.

It will usually absorb moisture if exposed to it.

It may naturally biodegrade in storage through a number of mechanisms, particularly if not absolutely dry. This will lead to loss of energy content and potentially the formation of moulds, the spores of which can be dangerous if inhaled.

A bigger store will allow larger, less frequent deliveries, a lower unit price for fuel, and more reserve in case of delays.

The storage of biomass must be well designed and constructed for a number of functions.

It must keep the fuel in good condition, particularly protecting it from moisture.

It must also be possible to deliver the fuel into an appropriate receptacle for transport, and convey it from there to its next destination conveniently and efficiently and requiring the minimum of additional energy input.

The primary purpose for the store will be to retain the biomass in good condition in a convenient place for it to be transferred to the next stage of processing, combustion or energy conversion.

In many cases one of the primary concerns will be to keep it dry. This means protecting it from direct ingress of rain, but also from groundwater.

It should also be protected during delivery of additional fuel, during transfer from the store to the next stage and also during access for maintenance.

A biomass store can be:

Size is important. There are many factors which will influence the optimum fuel store size but, as a general rule, bigger tends to be better. The ability to buy more at a time is likely to allow lower unit price, especially if deliveries can be scheduled to take a full load of one of the standard delivery lorries used locally. A larger store will also allow a longer period between deliveries and a greater reserve quantity when scheduling the next delivery giving flexibility in scheduling and in case of delay or delivery difficulties.

For most dry biomass stores good ventilation will be necessary to prevent the build up of condensation, allow additional drying, and to prevent the formation of moulds, the spores of which can present a serious health hazard if inhaled. The wearing of a dust mask by those working with such chips is advised.

Good air flow can also help to minimise composting of the fuel, leading to loss of energy content, and prevent the build up of excessive temperatures with the risk of fire. Advice from the US and Denmark suggests that heaps of wood chips should not be built over 8 to 10 m high for this reason.

If large stores are to be maintained then it will be necessary to ensure that the fuel is turned regularly. One mechanism that has been employed that requires minimal additional equipment is to withdraw fuel from the bottom of the store at a higher rate than is required and return the excess to the top of the pile.

Some form of drainage should be included, both in case of inadvertent ingress of water, and also if it is necessary to clean out the store, such as in case of fungal contamination.

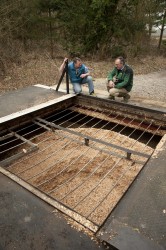

Building the store below ground may have a number of advantages, including ease of delivery from tipper type vehicles, the removal of the necessity for an additional, above ground structure, thereby potentially easing space requirements, and offering aesthetic benefits.

It is, however, likely to cost more than many above ground store designs, and it is particularly important to ensure that it does not suffer from damp from the surrounding ground. Ventilation and a drainage facility will be both harder to incorporate, and be more important.

There are particular issues with the storage of pellets, particularly concerning health and safety. There is more information about pellet stores on the separate page:

As part of the design for a biomass store it is vital to consider the various modes of delivery into it.

Depending on scale delivery may consist of:

In many cases it is most appropriate to make use of gravity to assist delivery, and design both the store, and access to it, to make the best use of this. This might entail:

Convenient access for any potential delivery vehicles must be designed in from the outset.

Also access for any construction and maintenance equipment that might be required for the store itself, or any associated equipment or structures must be considered.

Ease of extraction

Ease of extractionThe design and siting of a biomass store must also take account of ease of extraction of the content and supply to its next destination, whether this is a boiler, combustion unit, conversion plant or another site altogether. Use may be made of gravity, if this is convenient, thus reducing energy requirements.

It is important to design the store such that if the content is in a form that can flow, such as slurry, wood pellets or chips, this naturally brings the fuel to the take off point from the store. This take off point should not leave regions where the biomass can build up or get stuck, forming dead areas where it can stay indefinitely and potentially allow moulds to form.

For many stores the take off point will be at the bottom, feeding into an auger feed or an agitator, and it is important that this cannot become jammed with sawdust or other detritus.

There are many different methods for transferring biomass, depending upon its form. Possible methods include:Handling biomass

Different methods will suit different materials, situations and throughput.

With some fuels such as wood pellets it can be important to ensure that they are not handled too roughly as they can disintegrate into sawdust which may cause difficulties for subsequent handling, processing or combustion. This may or may not be of concern, depending upon application, but if it is, it must be considered at all points of handling and storage from production to usage.

It is generally considered best practice to minimise the number of handling steps with wood pellets. Resistance to mechanical handling will depend upon the quality of the pellet, pressure used in manufacture and any binders added.

There are particular issues related to safe storage of pellets. This page sets out some of the key issues of which to be aware.

The following guidelines apply to the design and operation of bulk pellet stores. Storage of bagged pellets in limited quantities is generally very safe, and it is sufficient to ensure that they are kep away from moisture and are not damaged within the bags by rough handling.

Good quality wood pellets have good mechanical durability and include low levels of “fines” (dust), and it is important always to buy good quality fuel. However even these can be damaged in transit, delivery and storage if care is not taken, or the store is badly designed. If pellets are damaged then they can crumble into fine, dry dust. In particular, if pellets are abraded during delivery they can generate an extremely fine dust and if this is allowed to build up and form a suspension in the air there is the potential to form an explosive mixture. While this is only dangerous if there is also a source of ignition, it is clearly a situation that must be avoided.

Another hazard can arise as a result of the potential for pellets to outgas carbon monoxide CO in storage. This gas is both flammable and toxic and so great care must be exercised to ensure adequate ventilation before entering an enclosed pellet store. This risk is considerably greater in larger stores. The HSE has issues a Safety Notice on the risk of CO outgassing in pellet storage.

Care in design and operation can keep the pellets in good condition and provide safe storage, however there are a number of guidelines that should always be observed. These will help to minimise damage to pellets during delivery and ensure there are no potential ignition sources.

The size of the pellet store should be considered carefully at the outset. It should be sufficiently large to allow at least the minimum delivery quantity of local suppliers (typically 5 tonnes, approximately 7.5 m3) without needing to be completely empty first. To allow a little “headroom”, a sensible minimum volume is 10 m3. Larger users will need a larger store, and a sensible minimum size is 3 weeks storage. A larger store will allow larger deliveries and this can often attract a lower price.

It is vital that the store is completely waterproof as pellets can absorb moisture and will crumble to sawdust. They will also expand during this process, potentially putting considerable pressure on the store structure. It also needs ventilation (filtered) to avoid the build up of condensation, however the structure should be sufficiently air tight, including appropriate seals on access doors, to prevent the escape of dust into other areas, in particular the boiler room.

If a person needs to enter an enclosed space that has been used to store pellets they must always ensure that it has been adequately ventilated before entry, that the door remains open while they are inside, and that they only do this under the constant supervision of a second person who remains in the vicinity, outside the store.