Summary

The term compression wood is used to describe the wood that tends to form in conifers on the underside of leaning stems, on the leeward side of trees exposed to strong winds, in crooked stems and in the lower part of trees growing on a slope. The structure and chemical composition of compression wood differs from that of normal wood. It can cause major problems in the wood processing industry, resulting in a deterioration in both mechanical properties and dimensional stability.

Darker compression wood revealed using transmitted light on a thin section.

Distortion caused by compression wood.

In 2000 the European Union approved funding for a shared-cost project under the Fifth Framework Programme, to increase knowledge of the way in which compression wood is formed with a view to linking raw material properties to the end product performance of construction wood.

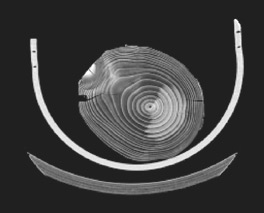

Optically scanned image of disc cut from 45-year-old Sitka spruce growing near the west coast of Scotland. Direction of prevailing wind is indicated by the arrow (i.e., wind flow is from left to right) and an area of severe compression wood is clearly visible on the leeward side of the disc.

(Photo courtesy of Franka Bruechert)

X-ray image of same disc illustrating density variations. The area of compression wood shows up clearly as the lighter coloured (denser wood) area on the leeward side of the disc.

The mechanisms of compression wood formation were studied along with the impact of site factors and silvicultural practices on its development and subsequent wood quality. The relationship between wood quality parameters and the properties of the end product was determined, in order to better meet the demands of the end user.

This research will help to integrate information about compression wood through the entire wood chain, from the primary forest production to the end user.

The output of the project is an advanced decision support tools in the form of predictive models linking silvicultural practice with raw material properties and the end product performance.

Compression Wood – Freiburg University activities and plans

Description of work already completed

The Institute for Forest Utilisation used several media to disseminate information on the Compression Wood project to the forestry industry, the timber industry and the wider public.

- On the Institute’s website a link has be established to the project’s main web page showing the main information on the project’s co-operation and management.

- A two-page leaflet summarising the details of the Compression Wood project was disseminated to the representatives of the German Saw millers Association at their yearly conference in October 2001.

- A short information note describing the aims and the focus of the Compression Wood project was published in the current notes of the “Gesellschaft zur Förderung der Holzforschung” in December 2001. The GFH is a body of members from university and the regional forestry and saw milling industry in Baden-Württemberg which acts as a focus-group to the forestry related research undertaken at Freiburg University, Forestry Department.

- An information note summarising the aims and the objectives of the Compression Wood project has been sent to the broadly disseminated German forestry and timber industry journals “Forst und Holz” and “Holz-Zentralblatt”. The note was already been published in “Holz-Zentralblatt“.

Description of work planned for next six-month period

- A web page with information on the relevance of compression wood, the project’s aims and IFU’s contribution to the project will be established.

- Opportunities to present the project to the public will be taken as they arise.

Activities and plans of Participant No 3a: Albert-Ludwigs-University Freiburg, Institute for Forest Utilisation

Work package number: 1.2 End User Focus Group – December 2001

Compression Wood – Swedish activities and plans

Swedish Website (SLU & Chalmers)

The English version of the Swedish website was launched in the beginning of November 2001. The address is www.sh.slu.se/compwood. The Swedish website will also be posted on a server at Chalmers during spring 2002.

Mailing list (SLU)

On the Swedish website people and organisations are able to join the Swedish mailing list. Information about the mailing list is presented in the first article in the trade journal NTT-Såg.

Article in Swedish trade journal NTT-Såg (SLU & Chalmers)

The article provides information about the project and the Swedish website. The article was sent to the trade journal, NTT-Såg, the 3rd of December 2001. The focus group for NTT-Såg is the Swedish wood working industry. The article will be published in January 2002. The article is also planned to be sent to another trade journal with the forest industry as main focus group.

Swedish website in Swedish (SLU & Chalmers)

In spring 2002 the Swedish version of the website will be working on both SLU and Chalmers.

The enquiry (SLU & Chalmers)

In spring 2002 an enquiry will be sent out to the Swedish timber processing industry by E-mail. The aim of the enquiry is to judge the economic aspects of the occurrence of Compression Wood in timber. Information about this enquiry is presented in the first article in the trade journal NTT-Såg.

Newsletters (SLU & Chalmers)

Newsletters will be sent to companies on the mailing list regularly (Twice/year). The aim is to inform about the progress within the project.

Meetings (SLU & Chalmers)

Our goal is to organise at least two meetings where we inform about the progress within the project. The meetings will be held in different parts of Sweden (Northern meeting/Southern meeting). If opportunity arises the project will also be presented as part of seminars on related subjects.

Work package number: 1.2 End User Focus group – December 2001

What’s of interest

SLU:

Swedish University of Agricultural Sciences

Chalmers:

Chalmers University